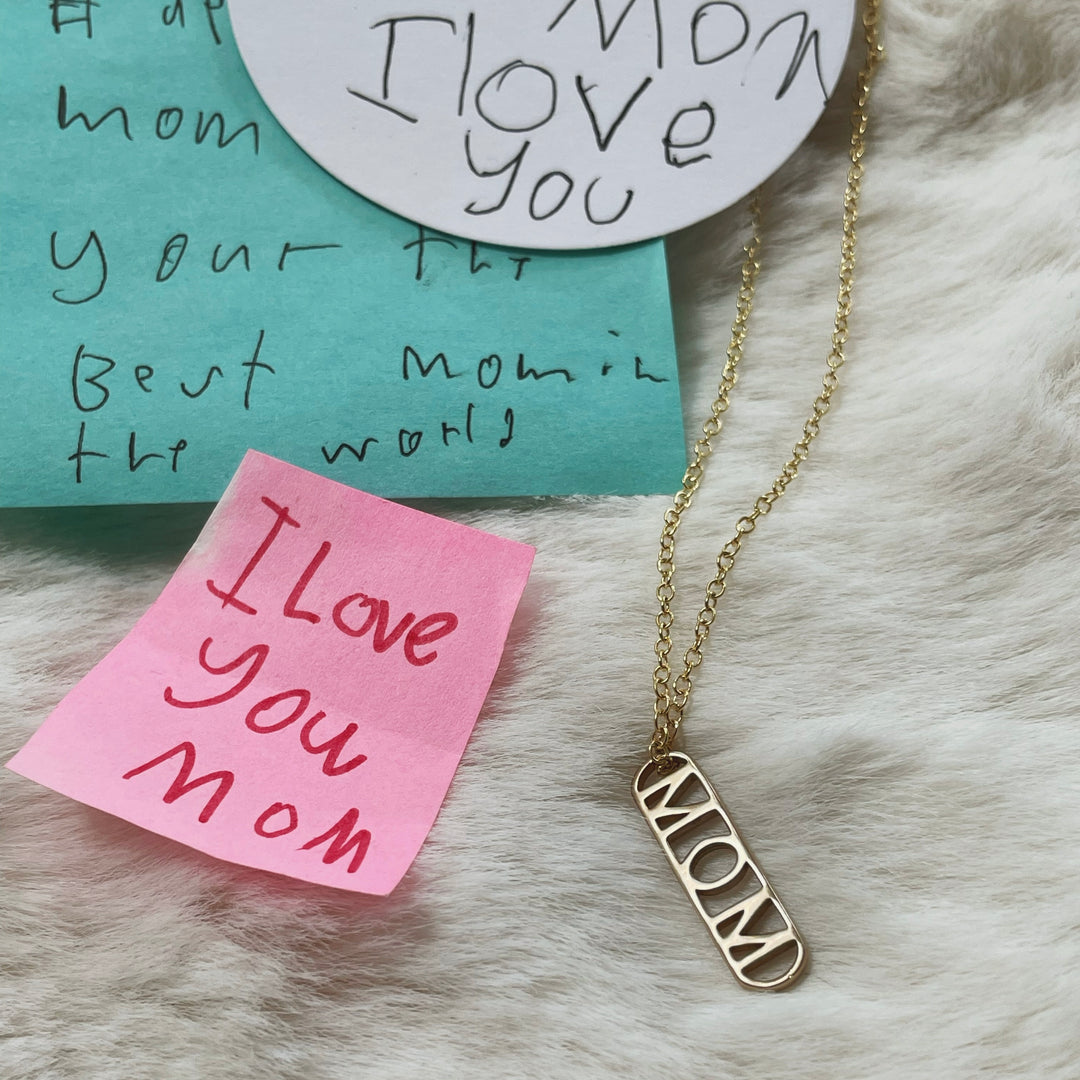

For over 16 years, we've created bronze, sterling silver, and 14k gold in our South Louisiana studio. We use Lost Wax casting to create designs inspired by landscape, culture, and the human experience.

mimosa collections

the big cats

MIMOSA'S BACKSTORY

LISTEN to us walk you through the early days of how we started and the behind the scenes of what we do and why we do it.